13:25:03 GMT+0000 (Coordinated Universal Time)

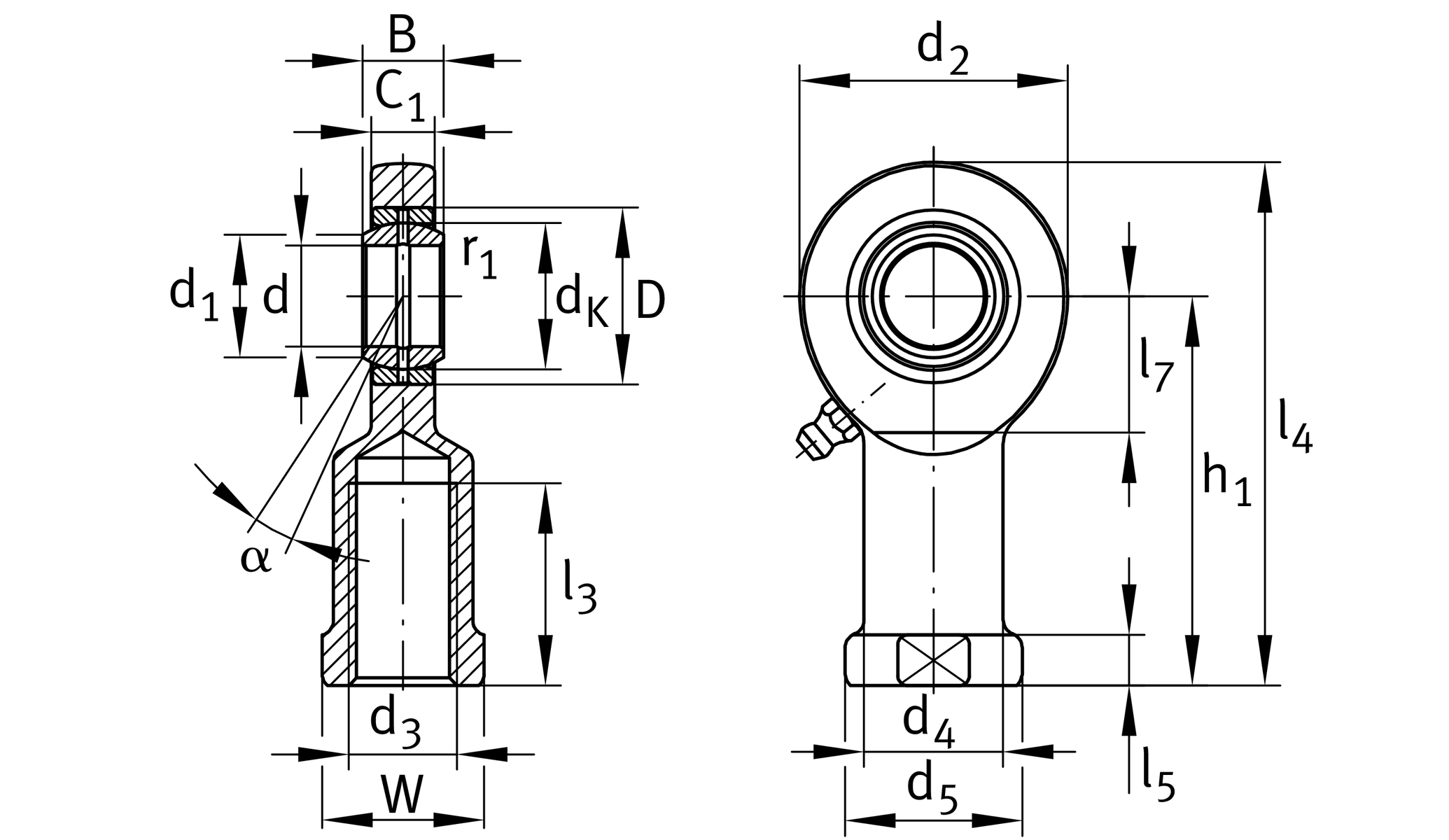

GIL25-DO

Rod end

Rod end with internal thread, left hand thread, requiring maintenance, sliding contact surface: steel/steel, DIN ISO 12240-4, dimension series E, type F, open design

Main Dimensions & Performance Data

| d | 25 mm | Bore diameter bearing |

| D | 42 mm | Outside diameter bearing |

| B | 20 mm | Width inner ring |

| Cr | 62,800 N | Basic dynamic load rating, radial |

| C0r | 88,300 N | Basic static load rating, radial |

| Gr | 0,037 - 0,1 | Radial Clearance |

| ≈m | 0.66 kg | Weight |

Dimensions

| dK | 35.5 mm | Ball diameter |

| d1 | 29.3 mm | Outer flange diameter inner ring |

| d2 | 64 mm | Outer eye diameter |

| d3 | M24x2 | Thread size |

| d4 | 33.5 mm | Shank diameter |

| h1 | 94 mm | Shank Length Internal thread head |

| C1 | 17 mm | Width of the rod end |

| α | 7 ° | Tilt angle |

| l3 | 48 mm | Thread length Internal thread |

| l4 | 126 mm | Total length internal thread head |

| l5 | 12 mm | Length rod end shank |

| l7 | 32 mm | Distance drilling with/shaft start |

| d5 | 42 mm | Shank diameter, large |

| r1smin | 0.6 mm | Edge Spacing |

| W | 36 mm | Width Across Flat |

| dOT | 0 mm | Bore diameter bearing, upper tolerance |

| dUT | -0.01 mm | Bore diameter bearing, lower tolerance |

| BOT | 0 mm | Width inner ring, upper tolerance |

| BUT | -0.12 mm | Width inner ring, lower tolerance |

| Grmax | 0.1 mm | Radial clearance, maximum |

| Grmin | 0.037 mm | Radial clearance, minimum |

Temperature range

| Tmin | -50 °C | Operating temperature min. |

| Tmax | 200 °C | Operating temperature max. |

Operating conditions for bearing GIL25-DO

In work for GIL25-DO

CO₂e caused by friction during operation

Comprehensive information with immediate calculations of the CO2e emissions of our rotative products in various application scenarios.

Load

*MandatoryMotion Influences

*Mandatory Preset calculation parameters

Arcanol MULTI2

Greasenormal cleanliness

Contamination70°C

Operating Temperature20°C

Ambient Temperature Choose your calculations

Powered by Bearinx

Please add the remaining conditions.

CO₂e emissions

For Production info_outline

-

Rating life

Total Rating Life (Lh10)

-

Static safety (S0)

-

Your feedback helps us to continuously improve our product.

All

English

2016-03-1 | Katalog | HG 1 | Englisch

Plain Bearings

Recently viewed products

Wait to see recently viewed products