14:56:19 GMT+0000 (Coordinated Universal Time)

6005-2RSR

Deep groove ball bearing

Deep groove ball bearing 60..-2RSR, single row, seals, steel sheet metal cage

Replaces

6005.2RS, 6005.2RSR

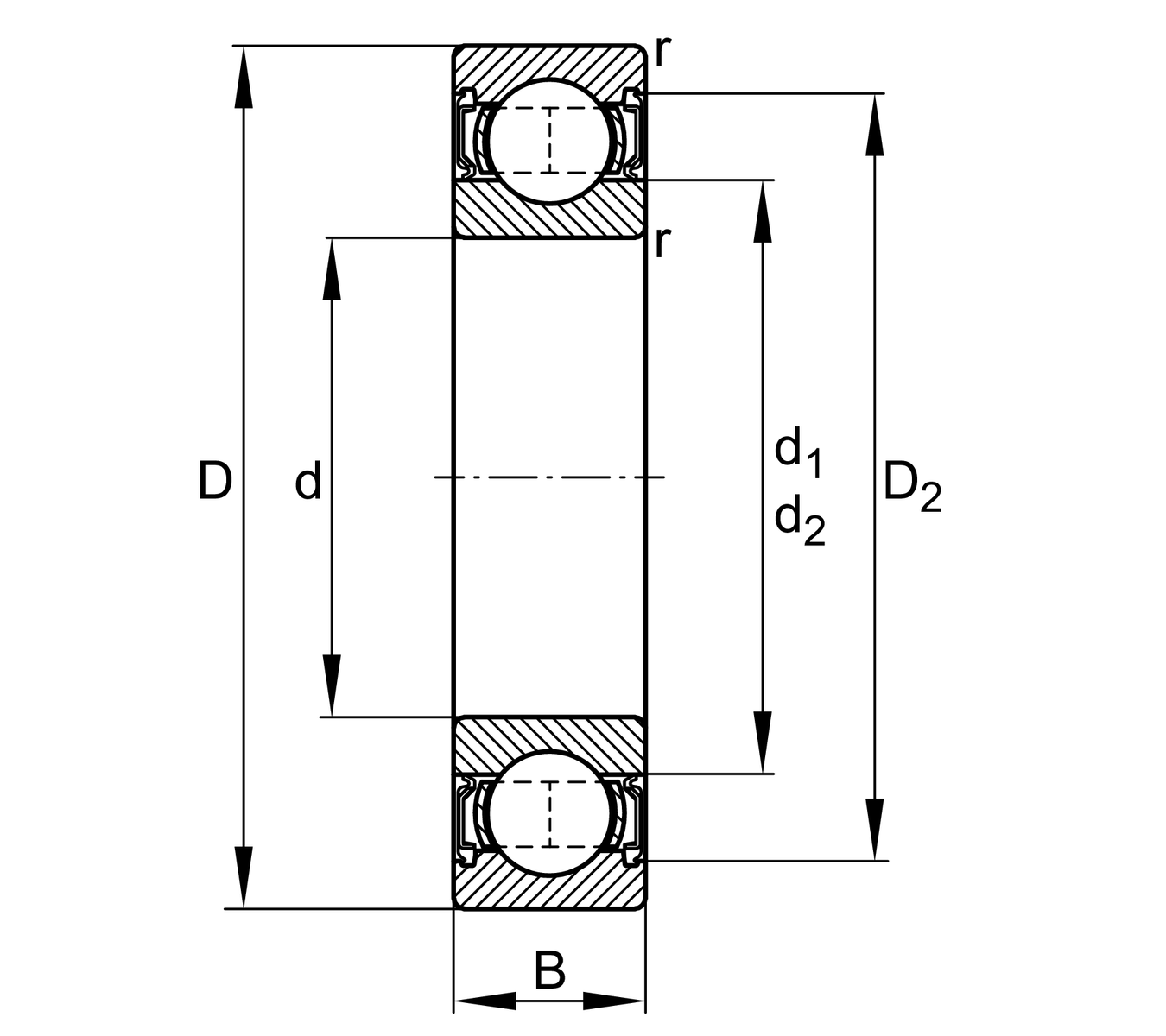

Main Dimensions & Performance Data

| d | 25 mm | Bore diameter |

| D | 47 mm | Outside diameter |

| B | 12 mm | Width |

| Cr | 10,700 N | Basic dynamic load rating, radial |

| C0r | 5,900 N | Basic static load rating, radial |

| Cur | 315 N | Fatigue load limit, radial |

| nG | 8,400 1/min | Limiting speed |

| ≈m | 77.2 g | Weight |

Mounting dimensions

| da min | 28.2 mm | Minimum diameter shaft shoulder |

| Da max | 43.8 mm | Maximum diameter of housing shoulder |

| ra max | 0.6 mm | Maximum fillet radius |

Dimensions

| rmin | 0.6 mm | Minimum chamfer dimension |

| D1 | 40.21 mm | Shoulder diameter outer ring |

| D2 | 42.45 mm | Caliber diameter outer ring |

| d1 | 32 mm | Shoulder diameter inner ring |

Temperature range

| Tmin | -20 °C | Operating temperature min. |

| Tmax | 100 °C | Operating temperature max. |

Calculation factors

| f0 | 14.6 | Calculation factor |

Operating conditions for bearing 6005-2RSR

In work for 6005-2RSR

CO₂e caused by friction during operation

Comprehensive information with immediate calculations of the CO2e emissions of our rotative products in various application scenarios.

Load

*MandatoryMotion Influences

*Mandatory Preset calculation parameters

Arcanol MULTI2

Greasenormal cleanliness

Contamination70°C

Operating Temperature20°C

Ambient Temperature Choose your calculations

Powered by Bearinx

Please add the remaining conditions.

CO₂e emissions

For Production info_outline

-

Rating life

Total Rating Life (Lh10)

-

Static safety (S0)

-

Your feedback helps us to continuously improve our product.

All

English

2017-08-15 | Katalog | MH1 Dismounting Hydraulic | Englisch

Dismounting of rolling bearings - Hydraulic dismounting

2017-08-15 | Katalog | MH1 Dismounting Mechanical | Englisch

Dismounting of rolling bearings - Mechanical dismounting

2017-09-15 | Katalog | MH1 Thermal mounting | Englisch

Mounting of rolling bearing - Thermal mounting

2017-08-15 | Katalog | MH1 Mounting Mechanical | Englisch

Mounting of rolling bearings - Mechanical mounting

2017-09-15 | Katalog | MH1 Services | Englisch

Services

2017-09-15 | Katalog | MH1 Tables | Englisch

Tables

2017-09-15 | Katalog | MH1 Technical principles | Englisch

Technical principles

Recently viewed products

Wait to see recently viewed products